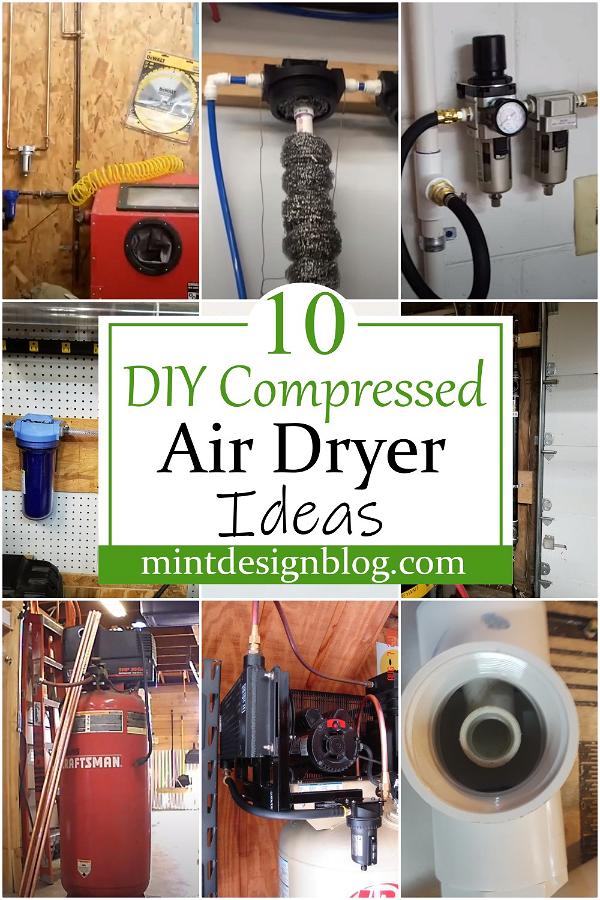

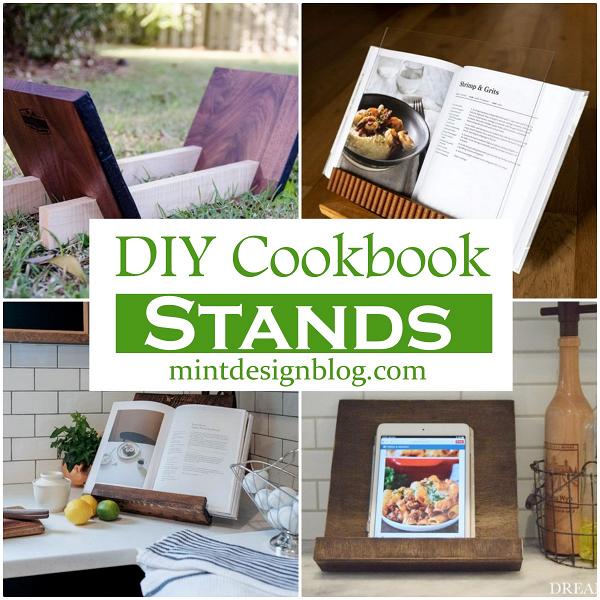

Looking for a way to save money and energy with compressed air? The DIY Compressed Air Dryer Projects provides instruction on building a compact air dryer, thus reducing your energy costs by quickly drying large amounts of air with less power. Compressed air dryers are a required piece of equipment for many industrial processes and businesses. If you don't have an air compressor, you can build your own DIY compressed air dryer from standard components found at hardware stores. This list of ideas has many variations, from simple air compressors to more complicated designs that use moving parts.

DIY Compressed Air Dryer Ideas

Compressed air dryers are a great way to save energy and improve efficiency. They can be used to dry the compressed air in your shop or factory, saving time and money while also reducing maintenance and wear on equipment. Suppose you have a compact air system at home or in your business. In that case, this article will help you understand how they work and teach you everything you need to know about designing and building your own compressed air dryers, with projects ranging from simple to complex systems with multiple compressor banks. These dryers create a dryer drop in pressure, which helps eliminate moisture mist. Compressed air dryers can also be used on high-pressure gas systems, such as those found in natural gas combustion engines.

Advantages Of Compressed Air Dryer

DIY compressed air dryers are a great way to save money on your compact air system. They're also easy to install and maintain, so you can spend less time worrying about your air compressor and more time doing what you love!

Here are just some of the advantages of DIY compressed air dryer projects:

- Cost-effective - DIY compressed air dryers are much less expensive than buying a new system from a professional contractor. Plus, they'll pay for themselves quickly because you won't have to buy replacement parts every few years!

- Easy to install - You can take care of DIY compressed air dryer projects on your own, so there's no need to hire an expert or wait for them to come out and do the work for you. Plus, there's no need to worry about getting all those permits and licenses that contractors may require before they start working on your project!

- Maintainable - When it comes time to fix something on your DIY compressed air dryer system, most of the parts are easy enough for anyone with basic knowledge of home repair or maintenance tasks (like changing out filters) to replace themselves without having any experience whatsoever in this field beforehand!

How To Make A Compressed Air Dryer System

This DIY compressed air dryer system is the answer if you want the most efficient way to dry your tools. It will cost you some money, but it’s worth it because it works better than most of the expensive ones on the market. A compressed air dryer system is one of the necessary tools in your workshop. It dries out the air to prevent the build-up of moisture, thus preventing corrosion and rust on your paint brushes and other woodworking equipment that may cause damage in the long run. If you have enough money, buying a compressor and an air dryer would be better. But if you are on a tight budget, this DIY guide will help you make one in no time.

DIY Air Dryer System

If you're looking for a way to air dry your clothes at home, this home DIY air dryer system is just what you need. This DIY air dryer system will help you turn the excess moisture in your indoor grow room into a source of free energy! Featuring a humidifier, evaporative cooler, and a ventilation fan, this is easy to make and maintain, which works wonders in any grow space to keep humidity low & save money on electricity costs. All the components are necessary to build a DIY air dryer system. Save money by drying your clothes naturally, save energy by cutting out your electric dryer and reduce your carbon footprint! This kit includes everything you need for a robust DIY project that is affordable, efficient, and economical.

Ultimate Compressed Air Dryer

If you have a compressed air system in your workshop, now is the time to set it up with a professional air dryer. This can be used for various tasks and has enough power to efficiently dry and clean air. With this video, you'll learn how to build an air dryer with an ultrasonic cleaner function that is perfect for keeping shop floors clear of debris. The Ultimate DIY Compressed Air Dryer is an affordable alternative to the many commercial kits for making a compressed air dryer. It's just as powerful, but unlike many others on the market, it's 100% unique with its own design.

Compressed Air Dryer Desiccant

How to DIY compressed air dryer desiccant cylinder. Use these in your industrial compressor to increase the oil's lifetime and get more work out of your compressor. This DIY Compressed Air Dryer Desiccant makes it easy to ensure that your shop's compressed air is dry and free from contaminants. It features a compact design, making it easy to fit into your compressed air system. This DIY compressed air dryer desiccant is a cost-effective way to dry moisture from gas streams, allowing you to reduce energy costs by as much as 50%.

Compressed Air Dryer Idea

This DIY compressed air dryer is built from an old air compressor, a water separator/filter, a ducting system, and more. It's also easy to assemble - follow the guide to build your own water-free dryer! This DIY project is easy and inexpensive. With this dryer, you can get your wet items very quickly dried up. This compressed air dryer is easy to build and can fit in the wall with some pieces of wood attached to the wall to enable the tubing and several other devices to hang on the wall. It's not time-lapse but real-time, so it's pretty easy to follow.

How To Make An Air Dryer

When you need to dry some moisture in your airline, you can quickly build this air dryer to do the job. This tutorial will explain how to make an air dryer using copper rubbing and pipe fittings. The creator treated the copper pipe to prevent rusting and filled all the holes with filler caulk. You can use this air dryer to remove unwanted moisture from your air system in your shop, home, or metalworking shop. If you need some dry air, then go ahead and try this video tutorial on how to build an air dryer.

Compressed Air Dryer For Your Workshop

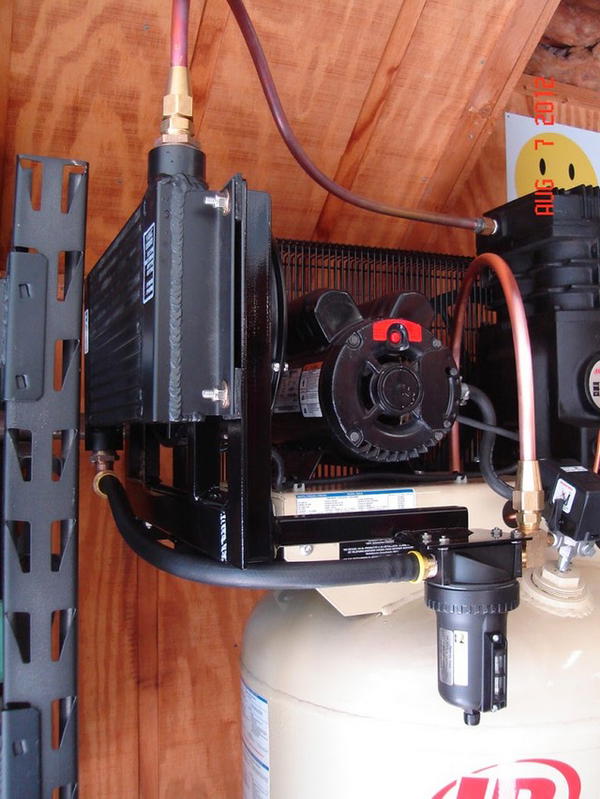

This DIY Compressed Air Dryer for Home Shop is a great project for anyone who does woodworking or projects in their garage, basement, or shop. When a tool is used in an environment where water or moisture may be present, the moisture can become trapped inside, which causes corrosion on moving parts. The simplest solution is to remove as much moisture from the air as possible before entering your workshop area. One way to do this is by having a compressed air dryer installed between your compressors and your tools, which will remove the moisture and take care of any other contaminants such as dirt and dust that would otherwise cause damage to those same moving parts.

How To Make A Cheap Compressed Air Dryer

A compressed air dehumidifier is an excellent tool for any shop that uses compressed air in its operations. Using a compressed air dehumidifier, your humidification system will not freeze up quickly, and moisture levels can be controlled throughout the year. You will save money on repair costs and replacement parts. They are also helpful in preventing rust on metal parts and tools. Building a compressed air dryer might sound complicated, but it requires minimal means and materials. If you have an air compressor, you can complete this project in just a few hours. The only downside is that it isn't exactly cheap, though that all depends on how much you want to invest. If the benefits of having one outweigh the cost, then this DIY is worth doing.

How To Dry Compressed Air Idea

Compressed air drying is a process in which compressed air is used to remove water from the container. Food manufacturers must follow strict sanitation guidelines to prevent contamination of food products. Contamination during production can cause severe illness or even death for consumers. Compressed air drying is a great way to improve compact air quality. It consists of an air compressor, filter, condenser, and dryer. This system will remove water vapor from the compressed air and ensure that you have clean and dry compressed air to use. While there are several ways to dry compressed air, this type is the most cost-effective method.

DIY Compressor Air Dryer Plan

This DIY Compressor Air Dryer is ideal for any engine or air-cooled equipment that must be lubricated with clean and dry air. The kit has all the necessary components to construct a professional-looking compressor dryer. Including everything but the engine and cylinder head covers. Air dryers used in refrigeration and air conditioning systems remove water from compressed air to minimize the possibility of corrosion, increase efficiency and extend compressor life. The DIY Compressor Air Dryer is an easy-to-build do-it-yourself project to build your own air dryer for your HVAC system.

See Other Projects

- DIY Shepherd Hook Projects

- 9 DIY Quilting Frame Plans

- 10 DIY Projector Ceiling Mount Ideas

- 10 DIY Power Bank Projects At Home